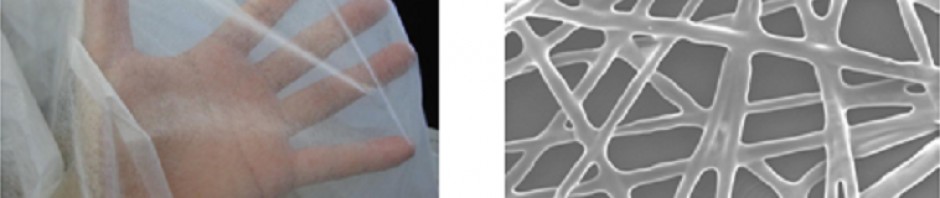

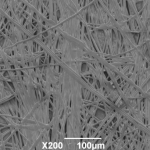

Ultra-Thin Nonwovens have been acquiring a key role in a high technology application. However, it is hard to manufacture Thin Nonwovens, especially, with the basis weight of less than 15 GSM (g/m2).

Hirose Paper manufactures Ultra-Thin Nonwovens which are much lighter than 15 GSM with good formation. The lowest basis weight which Hirose Paper has ever achieved are as shown below.

♣The Lowest Basis Weight Achieved by Hirose

◊ Polyester Nonwoven: 5 GSM

◊ Polyolefin Nonwoven: 2 GSM

◊ Vinylon Nonwoven: 8 GSM

♣Product Features of Ultra-Thin Polyester Nonwovens

◊ High Strength (Dry or Wet)

◊ High Dimentional Stability

◊ High Heat Resistance

◊ High Chemical Resistance

◊ High Weather Resistance

◊ High Electrical Insulation

◊ Low Cost

♣Applications for Ultra-Thin Nonwovens

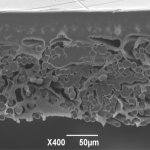

Ultra-Thin Polyester Nonwoven is used for Li-Ion Battery Separator.

Inorganic nanoparticle-coating enhances heat resistance and prevents thermal runaway.

Hirose’s uniform, high-strength, Ultra-Thin Polyester Nonwoven is suitable for the bucking layer of R/O Membrane which is used for desalination of seawater.

Hirose’s Ultra-Thin Polyester Nonwoven with metal-plating is thin, light and flexible. It prevents or diminishes electromagnetic interference in electric apparatus. Use of conductive adhesive layer enhances the easiness to attach to devices.

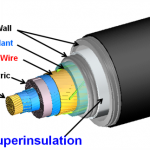

- Superinsulation 1

Insulated vacuum jackets are made of Thin Polyester Nonwoven and Aluminum foil. Nonwoven works as spacer separating foils. Nonwoven minimized heat conductance.

Ultra-Thin Polyester Nonwoven is suitable for Thermal Superinsulation Layer used for the High Temperature Superconductor (HTS) cable.